Materials Science and Characterization experts

Whether the work is in intellectual property, manufacturing support, failure analysis, quality control or research and development, NanoSpective provides a range of analytical services to meet our clients’ needs.

RESEARCH AND DEVELOPMENT

Some of the most exciting projects undertaken by NanoSpective are supporting the research and development of cutting-edge materials, applications and characterization technique development. We are always eager to explore options for collaborative projects with both private and public research sectors.

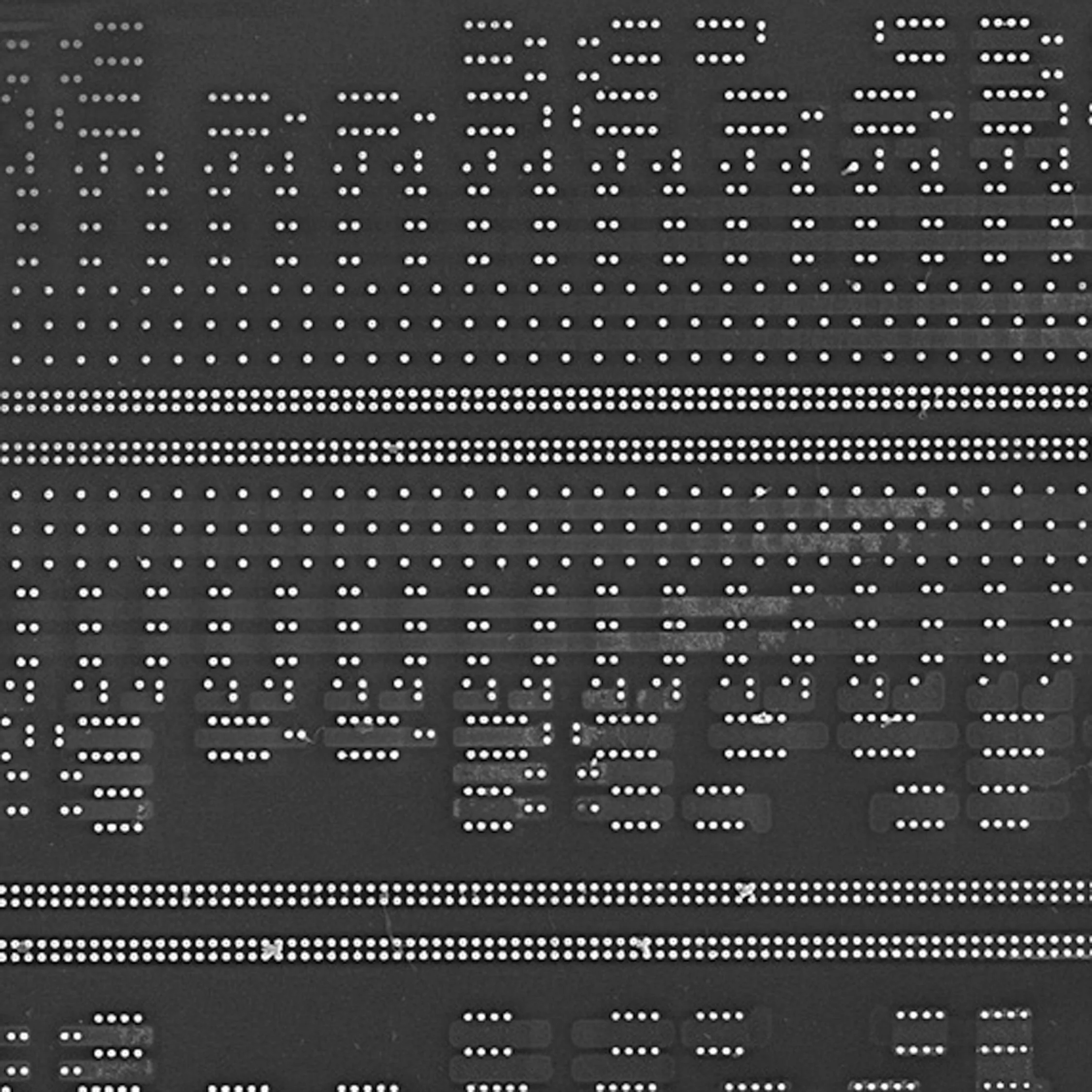

QUALITY CONTROL

Quality control processes are used to ensure that products meet specific requirements for dependability and performance. NanoSpective can provide the routine, rapid throughput characterization necessary for your testing needs.

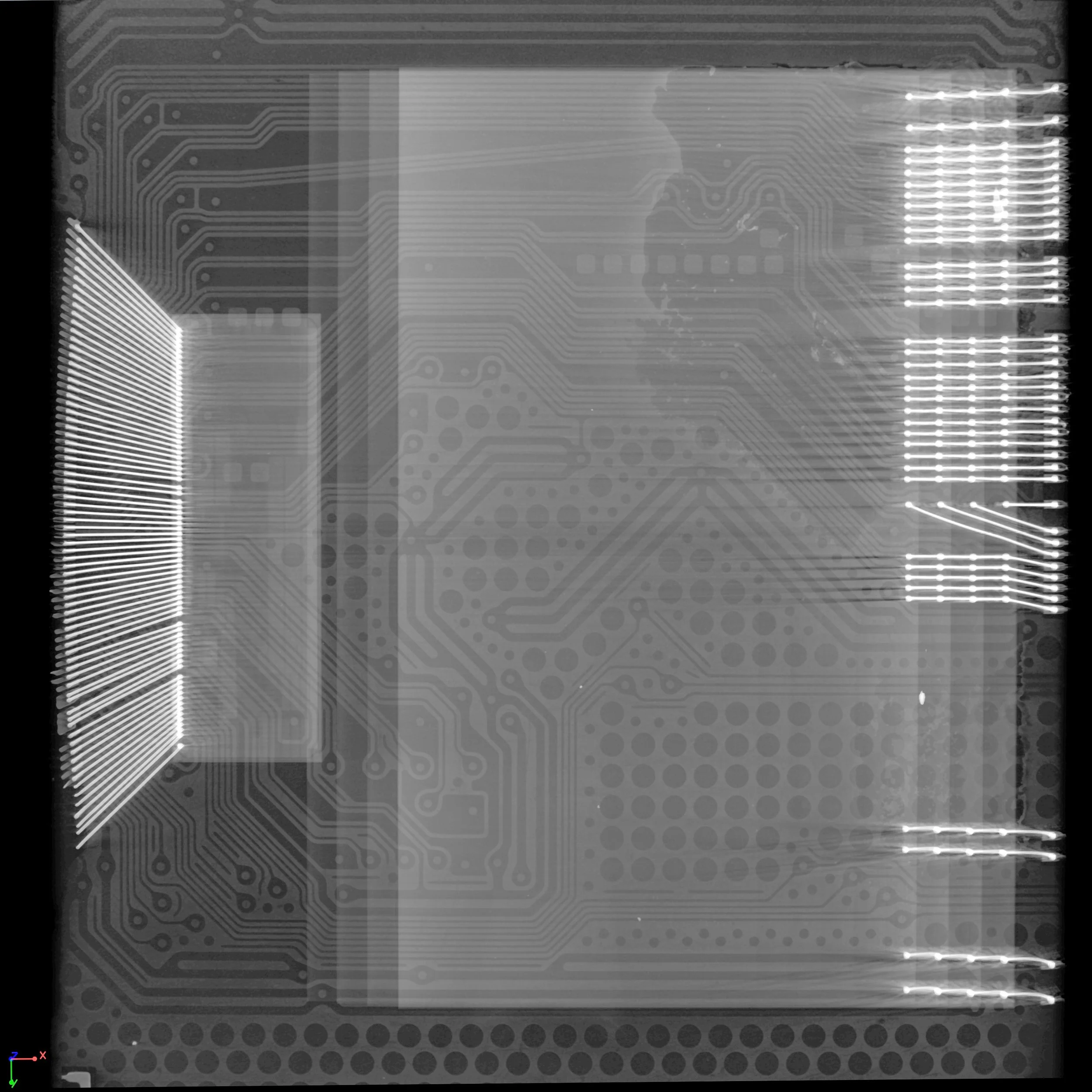

INTELLECTUAL PROPERTY

NanoSpective provides a suite of materials analysis and characterization services including reverse engineering in support of stakeholders’ patent infringement and patent assertion activities. Our scientists can authoritatively consult on materials characterization best practices.

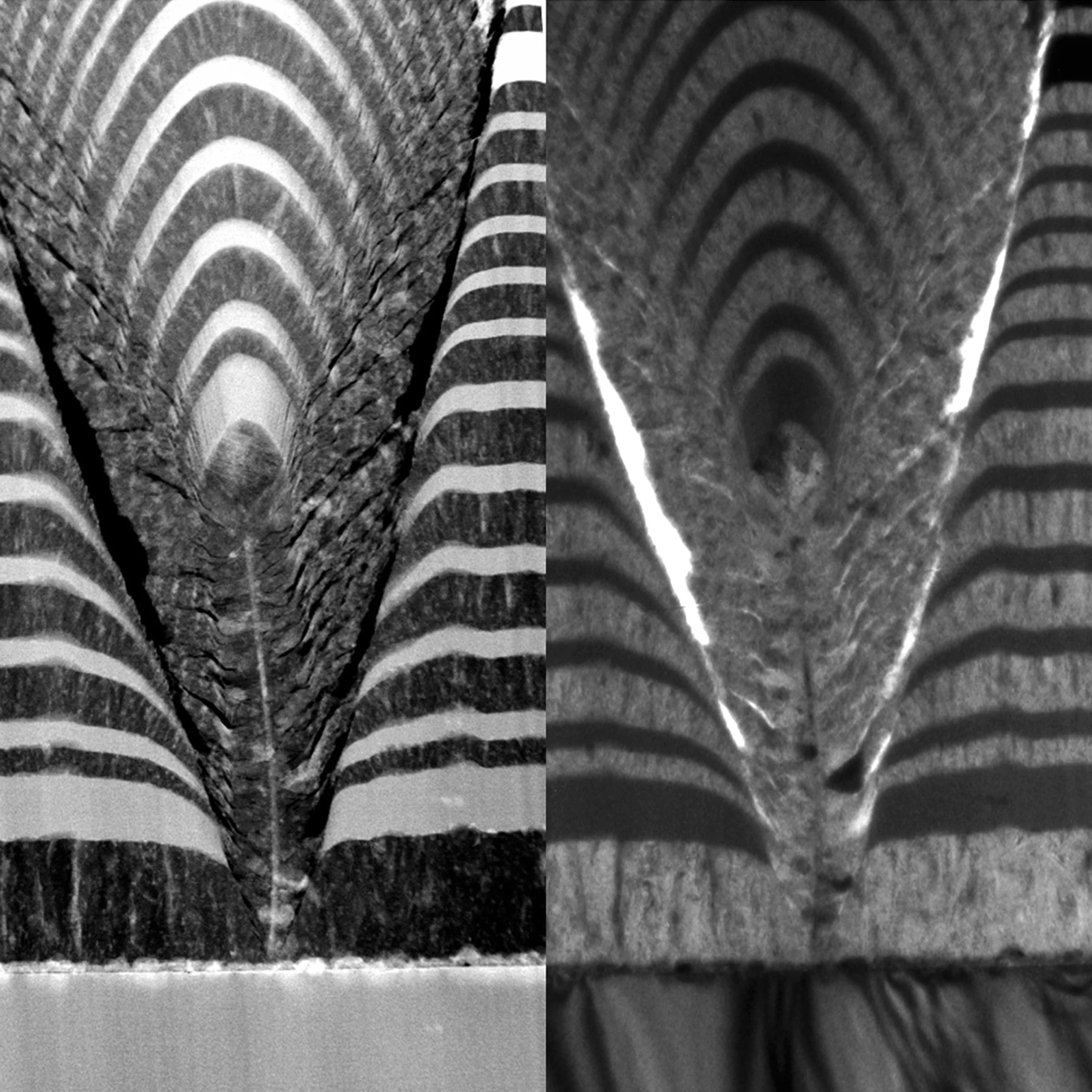

FAILURE ANALYSIS

Our services can be used to pinpoint and understand the root cause of defects and sources of failure in a range of products and components, whether detected while in service or during the manufacturing process.